FabIndia

|

Weaving Scale into Hand Made Products |

FabIndia is a well-known retail brand that sells various hand made products through its stores across India and overseas. They are probably the best-known urban middle class brand in India. It would not be wrong to say that they define the middle class look for Indians. Though they are best known for home linen and garments, they have expanded into organic food, personal care products, furniture and Jewellery. This 50-year-old company started as an export house, exporting Indian hand woven fabric to the developed markets in the west. In last 15-20 years the company has completely transformed itself into a chain of retail stores with more than 90% of its revenues coming from domestic markets. The company has been able to turn around and achieve rapid growth due and its innovations are worth exploring.

|

To understand how FabIndia operates, we need to understand the community-based businesses. In this model companies source products from communities that are traditionally well versed in a craft and make products using this skill. They are not formally trained, but they inherit this knowledge from their families and continue to pass it to the next generations. They usually operate in a small geography and have very limited access to the broader markets. Companies like FabIndia act as intermediary and take their products to the urban markets worldwide. There are many examples of the successful businesses built around communities like Amul that deals in dairy products and Jaipur rugs that deals with handcrafted carpets.

|

John Bissel started FabIndia in 1960 in New Delhi as a company that worked with various weavers across the country and developed fabrics that were sold to retail stores in western markets. For almost 30 years they kept growing at a steady pace adding both the suppliers and customers to their kitty. They started their first store in 1975 on an experimental basis which was a big hit, but the focus of the business still remained exports and that is where the maximum revenue came from. In early 90s when the Indian economy was liberalized and India opened itself to the world, the scenario began to change for FabIndia. Their customers now wanted to work directly with their suppliers. This was because they had an easier access to these suppliers, suppliers by now well versed to weave for the western tastes and also the volumes needed made sense for them to set up their own shops in India. On the other hand, Indians started making more money and were willing on spend on the merchandise sold in FabIndia stores, which till then was one of the few organized retail stores selling products made out of Indian hand woven fabrics.

By this time FabIndia’s baton had also moved into the hands of John’s son, William Bissell. It was more or less imperative that company has to change its focus from exports to domestic market for the reasons mentioned above. But the challenge was how to achieve scale in this business. The brand was built on hand made products, which could not be changed. For a large-scale supply of products, not only you need to work with many more communities in rural areas, but also ensure a consistent quality of products. Quality assurance in hand made products is a big challenge as each item is unique and since it is not coming out of a standard machine, there is no way to embed quality in the production process.

Challenge was to have an orchestrated supply chain, which not only caters to the need for large volume of supplies but the quality and type of supply had to be market driven. There was a need for a central co-ordination agency that can work with the suppliers to design new fabrics and styles based on the market trends and also ensure the quality of products reaching the retail stores. Now as the suppliers were based across the length and breadth of the country and specialized in products from their region, one central agency may not have been enough to deal with them. At the same time FabIndia also wanted to keep its well established partnership with the craftsmen and make them own a piece of enterprise that they work for.

FabIndia came out with an Innovative re-organization of company. It created 17 supplier region companies (SRC) that covered the entire country, divided by geographies. A minimum of 26% stake in SRC was reserved for artisans. FabIndia owns 49% stake and employees and investors own the rest. Twice a year the shares of these companies can be traded. Setup less than 5 years back, most of these companies are already profitable and pay dividends. A separate microfinance company was setup to provide funds to these SRCs.

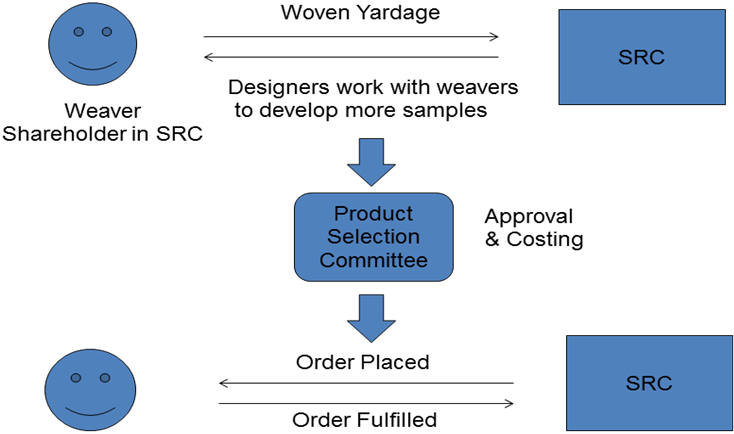

SRCs provide artisans with inputs on designs and market trends. They help them get access to funds and management skills and ensure the quality of products supplied to FabIndia. For FabIndia the quality control and sourcing has been decentralized and localized. As SRCs supply directly to the stores, the time to market is considerably reduced.

Typical Order Flow between Stores, SRC and Artisans / Producers

Key Innovations at FabIndia can be classified as:

Networking: Pioneering the concept of community-owned

Enabling Process: Decentralized Inventory management

Core Process: Decentralized quality assurance and mechanism for transmission of market signals.

Customer Experience: Standardized and consistent quality, Wide Variety.

Killer Questions

- Do we know why they have been successful?

- When do our processes function best?

- What are our net margins?